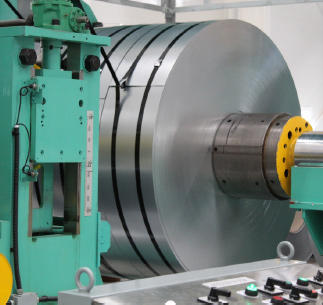

Steel Service Center

Discover unparalleled steel processing excellence with our Steel Service Center (SSC). Our cutting-edge technology ensures precise cuts, streamlined workflows, and versatile solutions for your projects.

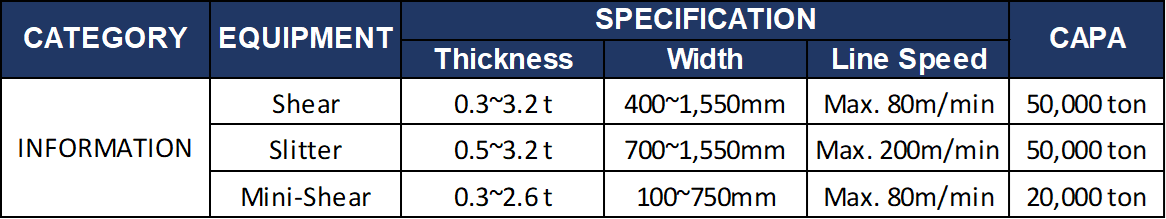

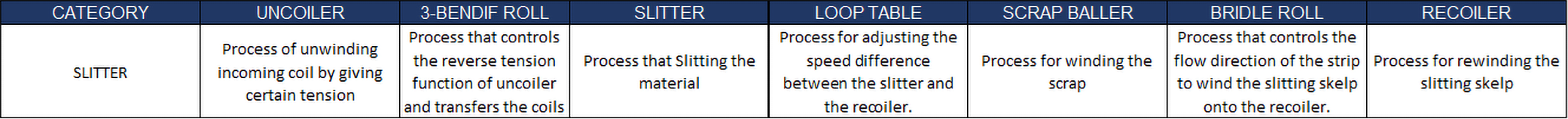

CAPA & PROCESS

PROCESS

CR

Commercial Cold-Rolled Steel Plate

As a steel material used for general purposes, it is used to make refrigerator doors, drums, and furniture. For automobiles, it is used for the roof, fender hood, quarter, oil pan, spring house, etc.

Steel Plate for Porcelain Enamel

According to the manufacturing method and end-use, it is divided into deep processing, processing, and general use. Deep processing and processing are mainly used for bathtubs, dehydration tubs, and general home appliance parts. The general use is used for kitchenware, etc., which are used 3 times or more without severe processing.

High Strength Steel

According to the manufacturing method and end-use, it is divided into general use, processing use, deep processing use, and TRIP-type high tension steel. The general use is mainly used to manufacture seat rail levers and parking brakes of automobiles. For processing use, it is used as a center floor and bracket. For deep processing use, it is used as a fender, hood, and for main exterior plate materials. TRIP-type high tension steel is used as a reinforcing material such as a door or a bumper and for other stiffeners.

HGI, CGI Plated Goods

HGI

A zinc plating steel plate is beautiful and has excellent corrosion resistance, so it is used in a variety of applications ranging from architecture, civil engineering, automobiles, home appliances, and household items by preventing the steel from being oxidation due to the zinc action of steel sacrificing.

CGI

Due to the high amount of zinc plating, it has excellent corrosion resistance and a uniform surface, which gives a beautiful appearance after painting. Used for furniture and office equipment, the interior and exterior of home appliances, the interior of automobiles, pipes, and construction materials.

EGI Plating Product

EGI

Often used after surface treatment such as phosphate treatment. Used for interior and exterior panels of automobiles and home appliances by securing quality through various post-processing.

PO Product

PO

Used in various uses such as distribution panel, automobile parts and steel pipe support as the product of removing surface scale of heat rolled coil by using hydrochloric acid in pickling process.

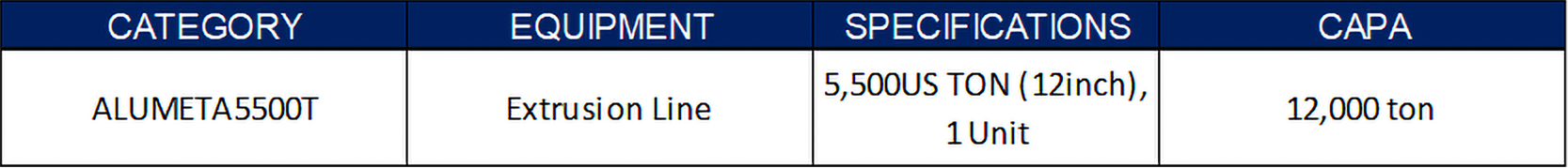

ALUMETA

EQUIPMENT

With expertise in aluminum profile production, we collaborate closely with our clients to understand their specific needs. Using high-quality alloys and advanced manufacturing processes, we ensure precision and durability in our products.

CAPA

BENEFITS

PRODUCT USAGE